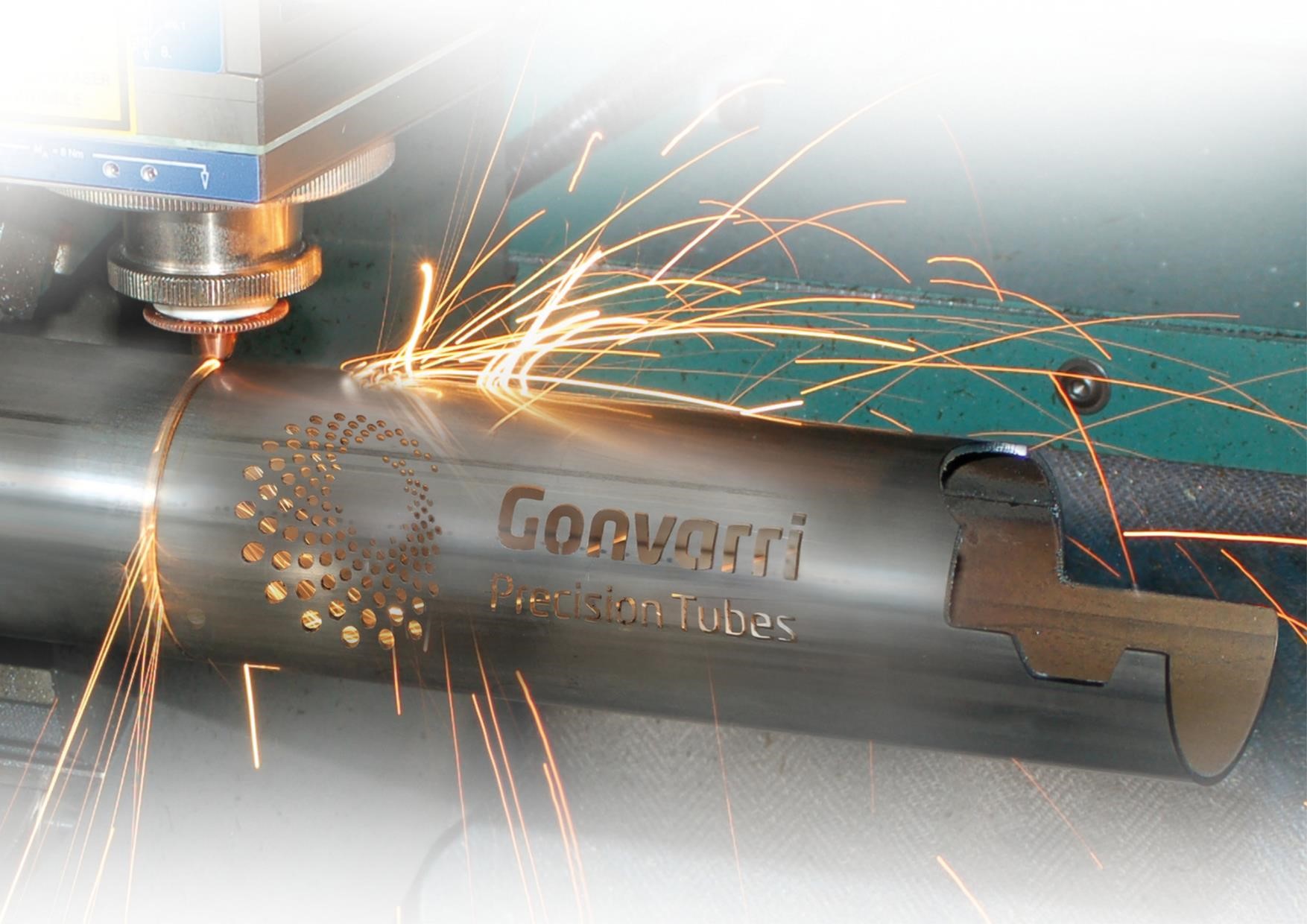

Precision tubes

Leaders in high precision carbon steel tubes

We manufacture high precision carbon steel tubes with the highest quality standards and the most advanced R&D.

Commitment to quality and innovation

At GPT we are firmly committed to innovation through research, an important pillar that allows us to continue developing competitive products that add value to our customers.

Some of our R+D+I initiatives have materialized in projects that have obtained the support of CDTI (Centro del Desarrollo Técnico Industrial) and have borne fruit in the registration of invention patents and the execution of integrated multi-company projects.

Quality control and certification of our products is one of our main priorities. In our research laboratory we study the crystalline structures of steels of advanced grades in order to select the most efficient steel plants.

A complete analysis system and a highly qualified staff allow the development of R&D&I activities, being one of the main improvement engines on which Gonvarri Precision Tubes relies for the optimization of its processes and the development of new products and services. Likewise, the close and close relationship with our customers complements the research activity through the feedback of the results and the approach of new challenges.

We adapt to your project needs

We achieve an extensive experience in the tube industry offering a wide range of products, from high-precision carbon steel tubes manufacturing, to disc and laser cut-to-size processes.

Carbon Steel Tubes

Cold calibrated and welded steel tubes for precision applications. We produce welded and cold-gauged steel tubes. According to standard EN 10305-3/-5 and Supply condition +CR1/+CR2.

Precision applications

Gonvarri Precision Tubes has several tube manufacturing lines that use HF (High Frequency) induction welding technology. The high quality standard of the products manufactured by GPT is the result of 30 years of experience and has recognised prestige both nationally and internationally.

State of the art steel tubes

Advanced High Strength Steels (AHSS) are the latest generation of steels that offer an effective solution to optimising weights and strength in most demanded parts and those with high requirements in shock energy absorption, especially in the automotive sector.Their cost is offset by the possibility of mass reduction, which makes them a technologically highly competitive solution.

Tubes for hydroforming

We provide the best precision tubes and we are specialists in tubes for hydroforming, one of the most demanded tubes on the market. Hydroforming is a very aggressive process to obtain complex shapes from round tubes.

Hardened tubes

Induction hardening is based on heating the material by passing it through a high density magnetic field. The heating penetration is a direct function of the working frequency.Precise control over this frequency ensures perfect hardening homogeneity throughout the section. The use of Mn-B alloyed steel grades guarantees a high level of impact energy absorption, a property of vital importance in some parts, such as the anti-intrusion reinforcements of vehicle doors.

Finitube®

GPT manufactures Finitube with great technical care from the beginning to the end of the process, using our knowledge acquired after more than 20 years manufacturing this type of tube.The FINITUBE® range provides the best surface finishing for those products that, due to their functionality and final use, are intended for components of high aesthetic quality, such as chrome and nickel plating, metallic paint, etc.

Ductitube®

Based on our own technology, DUCTITUBE® offers a list of optimised mechanical properties that allows the user to replace other tubes (standard/annealed) guaranteeing the required level of conformability and obtaining a relevant cost reduction.

Headrest Tube

We supply Normal E600 HRF tubes, which allow a tube bending with a medium radius and minimum deformation, while maintaining the quality of surface finish and sufficient wall thickness.Additionally, we manufacture Extraductile E600 HRF-ED headrest tubing, which allows a double curvature with close curves and a smaller radii of curvature. Deformation and wall reduction are lower, maintaining the quality of the surface finish. The Extraductile Tube for headrests reduces wear and tear on the tooling and offers more room for maneuver by deforming it.

More information

Green Steel, our model

for a better future

A Sustainable Management Model Sustainable growth is the best way to fulfill our mission and meet the expectations of our stakeholders. We integrate responsible management and a commitment to ethics, transparency and collaboration into our Sustainable Development model. In this way, we contribute to building a cleaner environment with fewer inequalities.

Presence in more

than 27 countries